| Demo : Aluminium Sheet |

Description

When final gauge earing is important and when it is developed by balancing anisotropy due to hot rolling with anisotropy due to cold rolling, a useful quality check is the earing at reroll gauge.

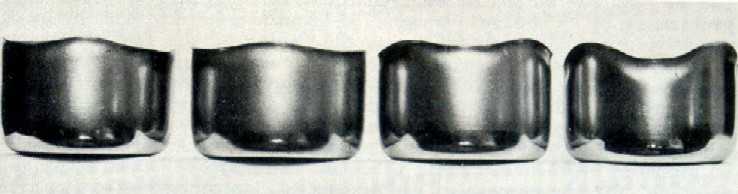

"Earing" is a phenomenon in drawn cups made from sheet metal and is seen as a series of protrusions around the rim causing the cup to have an irregular edge, as shown below.

The cause of this phenomenon is the non random alignment of the crystals of metal making up the sheet ("crystallographic texture"). To minimise earing the textures produced during hot rolling (ears at 0 and 90°) are balanced by those produced during cold rolling (ears at 45°). At final gauge this characteristic must be controlled to specified limits and this can only be achieved if the composition, homogenisation and hot rolling conditions are correctly adhered to. Regular checking of reroll earing is designed to ensure that the upstream processing conditions are correct.

Why is it important ?

If reroll earing is found to be outside certain values the product may have to be diverted to less demanding final products or scrapped.

How is it measured ?

Height of ears/height of cup as a percentage.